rockwell hardness test sample preparation|how to calculate rockwell hardness : wholesale By utilizing a few “best practices” in hardness testing such as closed-loop load monitoring, the appropriate preparation for test samples, repeated sample measurements, and adjusting measured values for gage bias, measurement .

WEB2 de dez. de 2021 · Para saber mais sobre Planilha Completa Sobre Ciclos, Maior Atraso, Frequência, Último Atraso para os resultados da Lotofácil, é só clicar neste link aqui ht.

{plog:ftitle_list}

Que boquete delicioso Karen oliver 5 min. 5 min Pornossp - 3M Views - 1080p. Menagem com a melhor amiga 13 min. 13 min Casal Porra Loka - 5.5M Views - 720p. Negao me fodendo gostosinho 2 min. 2 min Karen Oliver - 1.5M Views - 720p. Karen Oliver que boca e essa em que delicia 3 min.

The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with . Paramount to accurate and reliable Rockwell hardness results is ensuring that the operators and the methods used are following proper test technique and practice. The precise nature and exactness of a Rockwell test .

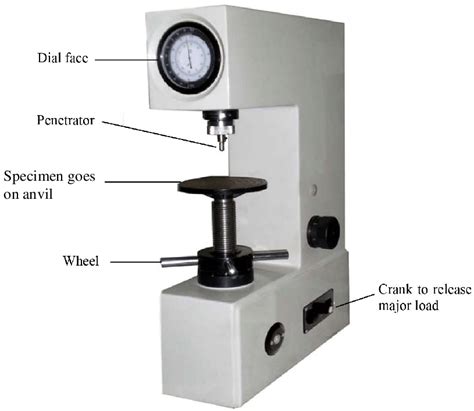

Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the . for testing hardness in plastics, like Shore (Durometer), Rockwell, the Ball indentation hardness test and Barcol. This Application Note will focus on hard-ness testing .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .

By utilizing a few “best practices” in hardness testing such as closed-loop load monitoring, the appropriate preparation for test samples, repeated sample measurements, and adjusting measured values for gage bias, measurement . The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load.

Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell scale) to 10 kgf (used in the “Regular” Rockwell scale). Total test forces range from 15kgf to 150 kgf (superficial and regular) to 500 to 3000 kgf .

1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth .The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for .

There are two types of Rockwell test (Table 23.1): Rockwell: the minor load is 10 kgf, the major load is 60, 100, or 150 kgf. Superficial Rockwell: the minor load is 3 kgf and major loads are 15, 30, or 45 kgf. Table 23.1: Some common .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .Learn all you need to know about materialographic preparation of different materials, metals and alloys – from sample preparation through to structure microscopy analysis – with expertise and insight from Struers, the world’s leading materialographic and metallographic experts. . The Rockwell hardness test. Rockwell is a fast hardness .There are two types of Rockwell test (Table 23.1): Rockwell: the minor load is 10 kgf, the major load is 60, 100, or 150 kgf. Superficial Rockwell: the minor load is 3 kgf and major loads are 15, 30, or 45 kgf. Table 23.1: Some common scales in Rockwell and Superficial Rockwell testing

Precision in hardness testing starts with the right support through hardness testing sample holders and anvils. Secure specimens, maintain stability during testing, and ensure the test surface is perpendicular to the indenter, guaranteeing trouble-free testing.

The 574 Series Wilson Rockwell Hardness Testers offer quality, durability, and an industry leading Gauge Repeatability and Reproducibility (GR&R) making this hardness testing machine best in class. This system is available in Regular or Twin Scale models and capable of testing in all of the regular and superficial Rockwell hardness scales and . Various sample preparation methods and the material surfaces resulting from them that have either been observed or could reasonably be anticipated were investigated to determine their influence on hardness testing. . Basics of Rockwell Hardness Testing, HOT TOPICS in Heat Treating and Metallurgy, Vol. 1 No. 1, November 2003. 2. Midea, Sandra . Material Preparation Tools; Training & inars; Join us for the next Microstructure & Analysis inar. November 13 2024 | 12:00pm CDT . Sample Holders; Platen Systems; Burst Dispensing Systems; . Rockwell Hardness Testing Calibration Kits;

The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . The preload is applied to the sample and held for a specific time. For Rockwell methods the preload is 10 kg. For Super-ficial Rockwell methods the preload is .

(ISO), provide specific requirements and procedures for Rockwell hardness testing. The intention of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplement the information given in test method standards with good practice recommendations. Although this Guide

All information about the Vickers hardness test Test procedure Sample request for the Vickers method Vickers hardness Hardness Discover now. . even if sample preparation is necessary and the evaluation of the hardness value is time-consuming. . (compared with the Rockwell method). The test cycle takes somewhere between 30 and 60 seconds .The Rockwell hardness test is a non-destructive testing method that is used to measure the hardness of materials. . For Rockwell Hardness Scale C (HRC): Typically, the sample should be at least 0.6 to 1.0 mm thick. For Rockwell Hardness Scale B (HRB): . There is no need for material preparation. Requires a smooth, flat surface for accurate .This eLearning course focuses on Rockwell and Brinell hardness testing and Vickers and Knoop microhardness testing. Participants will learn about how the tests are performed, test sample requirements, test parameter selection, and testing requirements. The course can be completed in 30 minutes.

The 574 Series Wilson Rockwell Hardness Testers offer quality, durability, and an industry leading Gauge Repeatability and Reproducibility (GR&R) making this hardness testing machine best in class. This system is available in Regular .Designed to provide a fully automated, dedicated, and lean hardness tester, the Wilson VH3100 is the workhorse of the VH3000 series. Featuring a load cell range of 0.05-10kgf and 3-position virtual turret, this system significantly reduces complexity by aligning its indenter, objectives, and overview camera at a fixed location.Buehler's industry leading hardness testing blocks ensure accuracy, integrity, and traceability in hardness testing processes. . By applying our expertise in sample preparation and high-quality production, in-house processing delivers test blocks with the highest quality surface finish. . Wilson Rockwell Hardness Test Blocks;

Principle of Rockwell hardness testing . Max. hardness of sample940HV 940HV 1000HV 650HB Preparation of surface * Roughness class ISO N7 N7 N5 N9 * Max. roughness depth Rt 10 µ m 10 µ m 2.5 µ m 30 µ m * Average roughness Ra 2 .The 574 Series Wilson Rockwell Hardness Testers offer quality, durability, and an industry leading Gauge Repeatability and Reproducibility (GR&R) making this hardness testing machine best in class. This system is available in Regular or Twin Scale models and capable of testing in all of the regular and superficial Rockwell hardness scales and . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. . Sample preparation: Ensure that the sample surface is properly prepared, free of contaminants, and has a smooth, flat surface. Inconsistent surface conditions can .

rockwell hardness testing procedure pdf

Below is a list highlihging a few of the most common methods used in hardness testing: Rockwell Hardness Testing: Measures the permanent depth of indentation; . Preparation of the sample: The sample should be prepared so that it is clean and has a flat surface for testing. If necessary, this can involve grinding, cutting, or mounting the .

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness TestingBest Practices for Rockwell Hardness Testing Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years. As a material property, its value and importance cannot be understated; the information

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small .

The most basic and commonly used definition is the resistance of a material to permanent, plastic deformation. While other forms of hardness testing, such as rebound, electromagnetic, and ultrasonic, are used in a variety of applications and measure material hardness through other techniques, indentation hardness testing provides reliable, straightforward, and a commonly .

how to test arm torsion strength

how to test for sacral torsion

Dive into the exciting world of Loli Hentai at Hentai.tv, where fantasy meets art at its most daring and provocative. Explore a carefully curated collection that celebrates the beauty and unique charm of petite female figures in adult anime. . Onii-chan, Asa made Zutto Gyutte Shite! Episode 4. Onii-chan, Asa made Zutto Gyutte Shite! Episode 3.

rockwell hardness test sample preparation|how to calculate rockwell hardness